If we are to change today’s building practices, we need to meet and share knowledge and experience at all levels of the industry. That’s why it was gratifying that among the 60 attendees were builders, building materials manufacturers, architects, contractors and recyclers.

Traffic light method for reuse in renovation projects

When Betonmast Trøndelag was commissioned to refurbish and build Trondheim Cathedral School in 2022, there was a clear desire from the client, Trøndelag County Council, to look at existing buildings as a source of reused materials. Sondre Synnevåg of Betonmast presented the project, which had a collaborative development phase and included a reuse survey to see which materials could be suitable for reuse and how easily they can be dismantled.

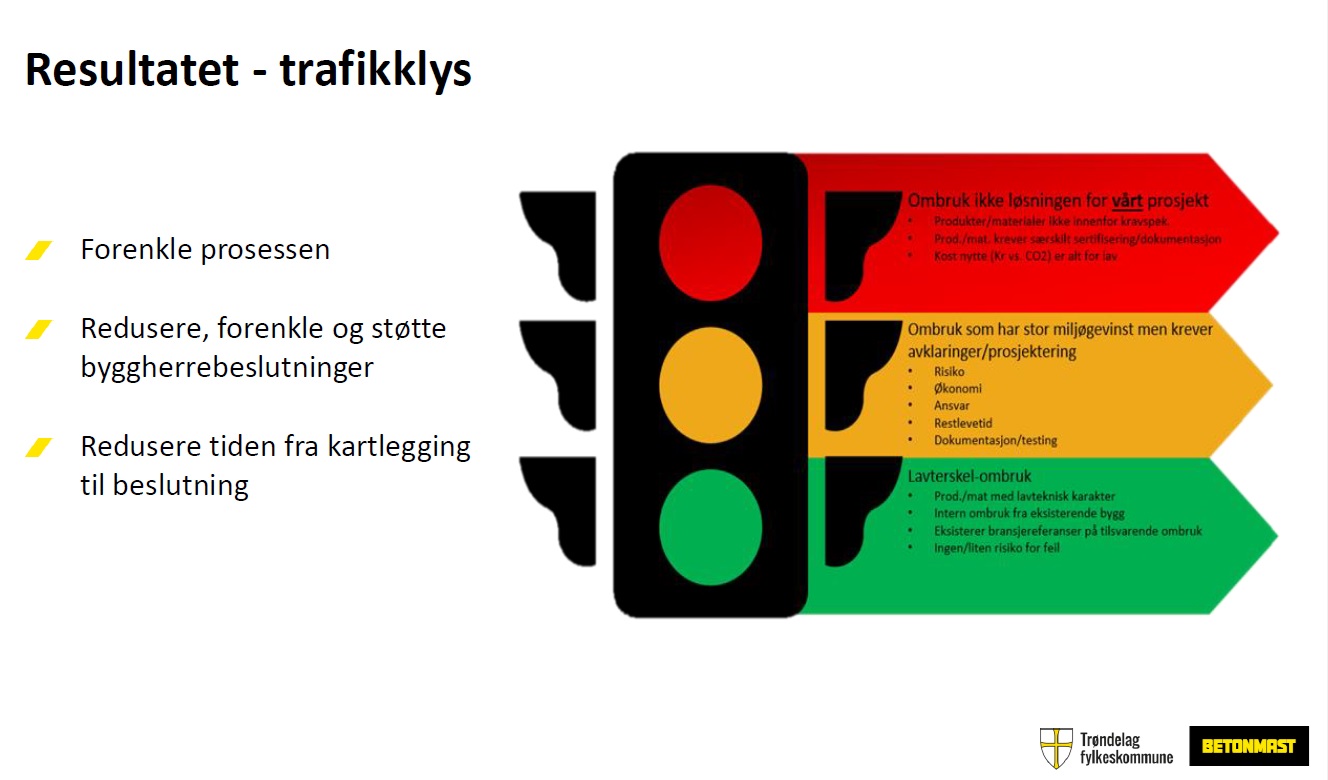

All materials that were defined as “suitable for reuse” were put into a decision matrix to clarify whether reuse would be profitable. The “traffic light model” was established, where Green = low threshold for reuse, Yellow = unsure of the dismantling or reuse potential, Red = not suitable for our project. Whatever fell into the Red category, it was up to the developer to decide whether it should be demolished/thrown away, or sold elsewhere – in which case the income was transferred to the project.

The rehabilitation of Trondheim Cathedral School has shown that it is possible to make the reuse of materials a profitable part of a construction project. The recommendation from the contractor is not to be afraid of tackling the issue, but to make sure you have all the decisions ready before you start demolishing and building. Heather Mason from the county council added that the project had applied for funding from Enova and Klimasats, not large sums of money, but enough to provide scope to try new things and at the same time relieve the contractor of risk.

Do you want to learn more about the traffic light method and the Trondheim Cathedral School project?

-

Watch recording of of the webinar “Contract forms for reuse” (Circular Resource Center 27.11.2023)

-

Read more about the about the construction project at Betonmast Trønelag

Reuse of interiors and bricks

Today, interiors account for a large proportion of greenhouse gas emissions over the lifetime of a building, because the interior is usually replaced every time the building has new users or tenants. But does it have to be this way?

Kirsti Svennung is head of No.17 – a sustainability network for interior architects, and she talked about how we Norwegians suffer from “renovation sickness”. “140,000 tons of office furniture are thrown away every year. And that’s not counting walls and floors. What are we losing by letting “renovation sickness” go? We know that 80% of the footprint is in the design phase. Svennung was concerned that aesthetics requires a new language, we need to ask other questions, including how we view durability. Should we accept that a “good chair” lasts for 7-10 years, is that good enough?

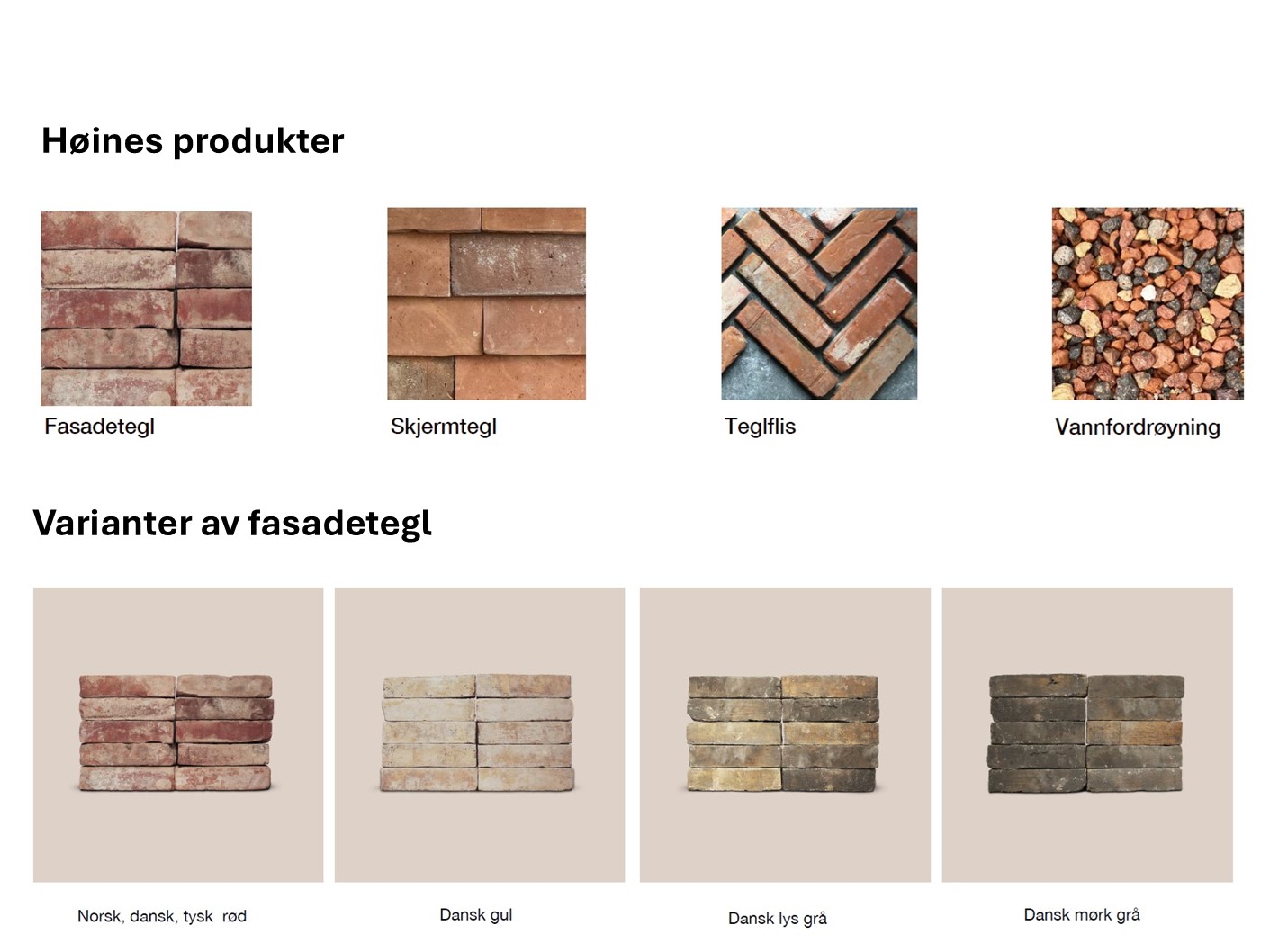

Product longevity is also important to Høine, which specializes in reusing bricks. Every year, around 50,000 tons of bricks are thrown away in Norway, while at the same time 40,000 tons of new bricks are built. The production of new bricks requires large amounts of energy; the bricks are fired at 110 degrees for three days. Brick is robust and durable, so why not use it several times?

Oskar Bringager, Marketing Manager at Høine, explained how the company has worked on a number of challenges since its inception in 2019, from CE marking to cleaning methods and logistics. They are now also working on introducing lime as a mortar in new brick buildings, to make it easier to dismantle the brick at the next crossroads.

You can read more about Høine’s work and construction projects HERE.

Logistics and market for reused materials

Today, Norway is one of Europe’s least circular countries, with a modest reuse of 2.5% of resources. In the EU and the government, the goal for the construction industry is that 70% of the waste should be reused, and thus one must expect constantly new rules and restrictions.

The recycling companies Sirkula and Østlandet Gjenvinning (ØG) want the building materials they currently receive as waste to be reused to a much greater extent. That’s why they have developed a pilot project for a reuse center in Inland Norway, and are now working on ownership and financing.

The plan is to start with a reuse center near Hamar, but at the same time establish a digital platform that makes it possible to trade reused goods without intermediate storage. The reuse center will support the professional players; contractors, real estate companies and builders. The short-term goal is to reuse as much as possible, but within three years the aim is for the business to be profitable.

The project was presented by Ingrid Staveland Reppe from Sirkula and Jon Inge Kjørum from ØG, who encourage the entire industry to work together on the establishment of a reuse center, which they believe will be crucial to meet future rules and requirements for reuse.

You can read more about the reuse center HERE

Possible local measures for increased reuse

The session was rounded off with a “World Cafe”, led by Christopher Mc Cormick from Klimavennlige bygg Innlandet. The aim was to involve the bright minds in attendance in solving the challenges of the future around reuse, and here you can see some of the input:

Experience sharing and pilot projects:

– Arrange an experience gathering with reuse projects from Inland Norway

– Start pilot project(s) with documentation of climate benefits and learning

Construction site and supplier collaboration:

– Test local solution for material accounting on construction sites

– Enter into an agreement with local packaging manufacturers on a circular test scheme

Value chain and tool support:

– Influence builders to introduce reuse requirements in procurement

– Develop local LCA module that includes reuse, in collaboration with educational environment

Responsibility and interaction:

– Gather stakeholders in a joint meeting to clarify roles in reuse projects

– Create a checklist/template for roles and responsibilities through project phases

Communication and attitude change:

– Develop a visual campaign: “Reuse is quality”

– Involve pupils and students in the development of new expressions and solutions based on reuse

Logistics and infrastructure:

– Establish test of physical intermediate storage in the Hamar region

– Pre-project for digital logistics platform (availability and timing of materials)

The reuse center in Innlandet:

– Working group with public and private stakeholders

– Preliminary study with mapping of location, players, operation and financing

The next professional gathering for the Construction Industry of the Future in Inland Norway will be held on Thursday, October 30 in Hamar.

Information is shared through newsletters and the website www.klimavennligebygg.no.