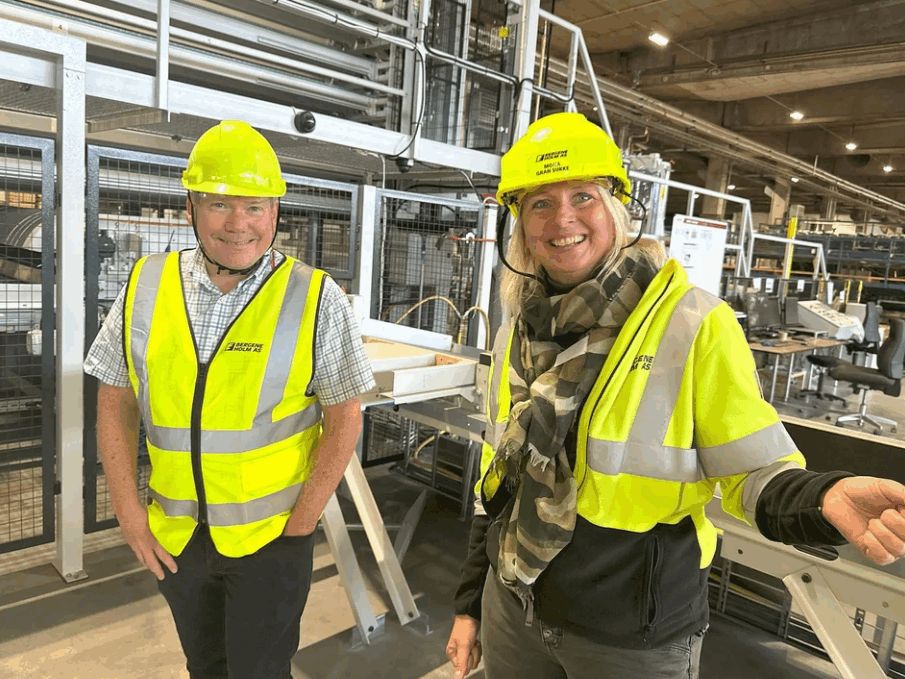

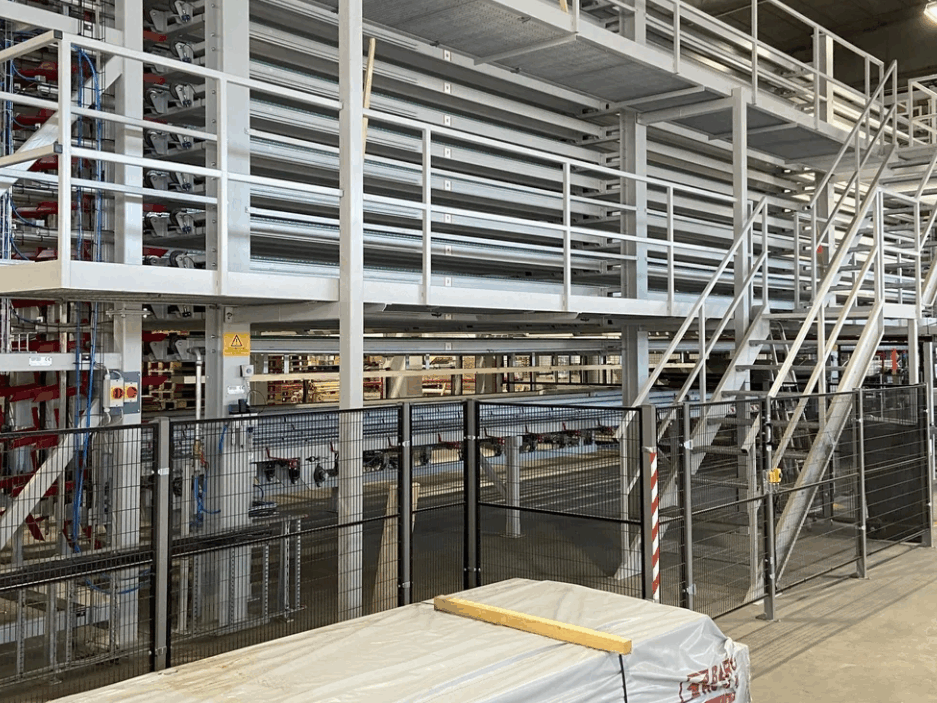

The Norwegian Wood Cluster administration recently visited Bergene Holm’s new flagship in Hof in Vestfold. There we were presented with the new cutting plant, which is connected to a sophisticated system of sorting pockets to sort lumber according to the customer’s exact order.

As little waste as possible

– “At Bergene Holm, we are committed to sustainability, and here we have taken an important step to reduce the amount of waste in the value chain,” says Sustainability Manager Hege Voll-Midtgaard at Bergene Holm.

She explains that on average, an element factory has 5-6% waste, while waste on construction sites can be as high as 25%.

– In addition, we cut away an average of 2.5% when we go from falling lengths provided by the forest to foot-cut loads requested by Bergene Holm’s customers. These are resources that should have been better utilized, and we have done something about it through the EKSAKT concept,” says Voll-Midtgaard.

Committed to product development and innovation

– “We work continuously with product development and innovation. In recent years, there has been a particular focus on waste-free construction sites, which is the reason for our investment in EKSAKT,” says Innovation Manager Mona Gran Sukke, Bergene Holm.

She explains that they have seven decreasing lengths lying in front of the saw in order to optimize cutting in the new facility. These seven lengths are optimized against several cutting orders, so that the cutting machine can always utilize each wooden plank with the least possible waste. In this way, all raw materials are utilized with minimal waste in the company’s own production, at the same time as no waste is delivered to the next link in the value chain.

– With the new facility, we can deliver exact lengths, exact labeling, exact packaging and delivery. The goal is exact assembly in industrial production and on major construction sites. With EKSAKT, waste on construction sites is minimal,” says Gran Sukke.

Important to reduce waste

– “It’s very interesting to see how Bergene Holm has found a way to minimize waste at the construction site, in element production and in its own industry. In the waste pyramid, this is the top level, so they have taken the measure that has the greatest value and found a solution to it,” says cluster manager Berit Sanness in Norwegian Wood Cluster.

At Bergene Holm’s Haslestad plant, the company is gearing up for growth. Almost NOK 250 million is being invested in new raw material sorting, new drying channels and a new intake at the adjustment plant, in addition to the EKSAKT cutting plant. When we have completed all this, Haslestad will be lifted to a capacity of 400,000 m3 of timber.