“It would be nice to have a simple answer to that question,” says Marit Smidsrød from the project management team, “but there are a lot of factors that come into play, including the choice of materials, which we have chosen to focus on in this project, but also energy solutions, emissions at the construction site, location in terms of transport, land use, etc.

Reference values will come

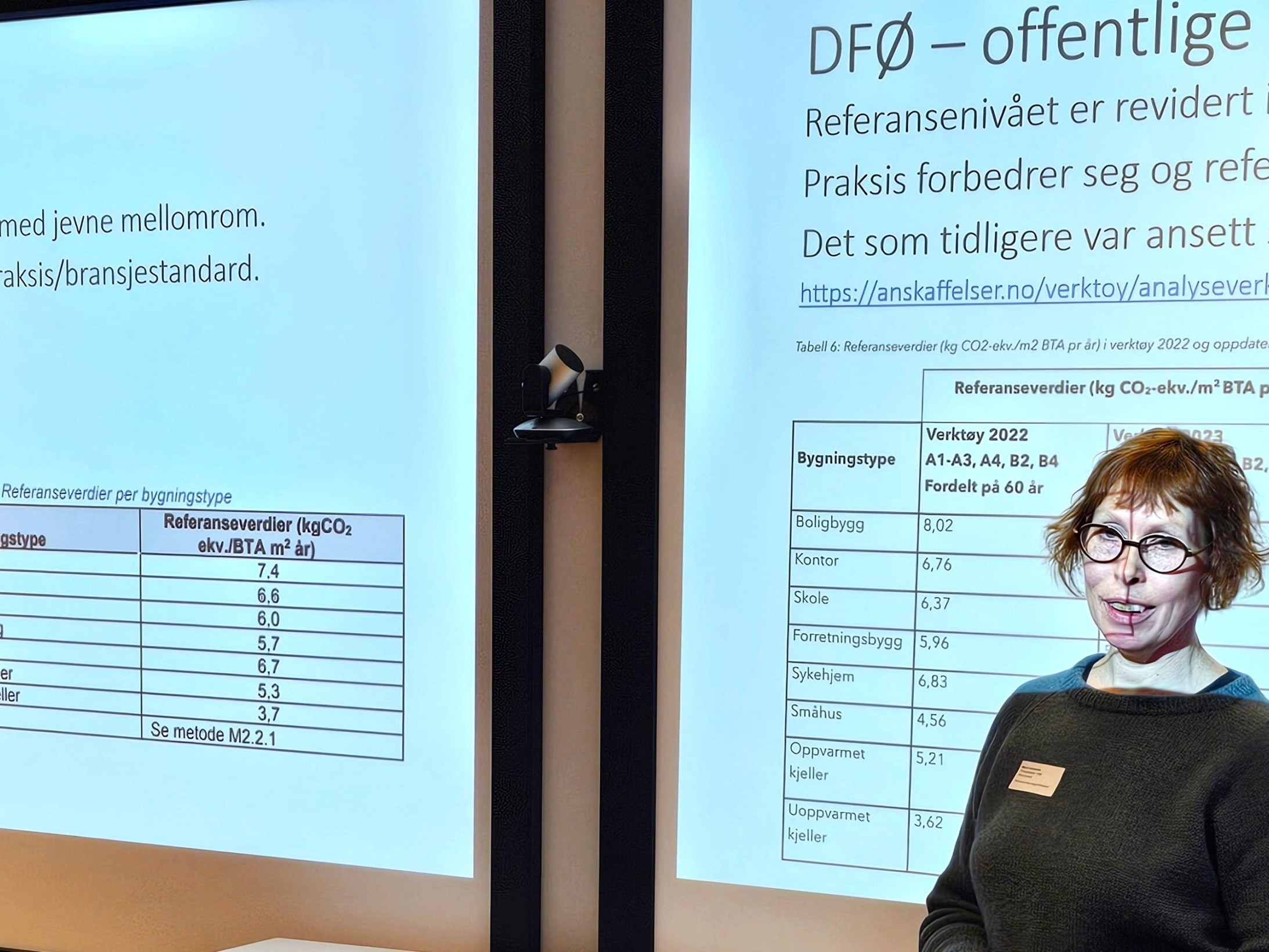

In July 2022, TEK 17 introduced a requirement to prepare greenhouse gas accounts for materials in apartment blocks and commercial buildings. So far, however, there are no requirements for how much greenhouse gas emissions the materials can have. “Both Denmark and Sweden have already adopted reference values for greenhouse gas emissions in buildings. In Norway, similar work is underway, but we don’t know anything about the time perspective,” said Smidsrød. “One thing is certain, however: requirements and criteria will be introduced. Among other things, this will mean that the public sector, which currently accounts for 10.3 million tons of CO2 emissions per year, will need more knowledge about the climate footprint of its procurements.

– We are committed to taking responsibility

Kjetil Ulset is employed by Gjøvik Municipality, and has participated in the project group and steering committee for Biri kindergarten and Biri primary school.

– As a municipality, we do not have unlimited money. But we do have guidelines for the climate, and we cannot ignore these. We have national and regional commitments that form the basis for our local guidelines, set out in Gjøvik municipality’s climate plan. One of the goals in the climate plan is to “reduce the climate footprint in the building and construction industry”, and then we must set requirements so that this is met, Ulset explained.

Want clients who set clear requirements

Hans-Jørgen Bjøralt is general manager of Backe Oppland, which was commissioned to build the school and kindergarten. The Backe Group is Norway’s largest family-owned construction company, and is the largest construction company in Innlandet (Backe Oppland and Martin M. Bakken).

– “In this project, the municipality set a number of requirements. It’s important to emphasize that these were requirements and not guidelines, which I think is absolutely essential,” said Bjøralt.

Examples of specific environmental requirements in the project:

The building must satisfy requirements for greenhouse gas emissions for materials including A1-A4, cutting and waste in A5, B4-B5 and C1-C4. The emission limit to be satisfied is 199 kg CO2/m2 GFA. Greenhouse gas emissions must be documented with calculations in accordance with. NS3720. Documentation must be available before the start of construction work.

Materials used must be low emitting. Emission requirements according to tab. 14 BREEAM Nor 2016 hea 02. The requirement applies to all interior materials and surface treatments.

– The municipality has used a number of requirements from the Breeam manual and selected requirements that are important to them. I think this is the right way to work. For this type of building, project-specific targets are more appropriate than Breeam certification. It looks different for a private developer selling a commercial building in an attractive area, where it may be worthwhile to deliver a high level of Breeam certification. But for public service buildings, a full Breeam certification can entail a lot that you have to pay for but don’t need,” said Bjøralt.

Examples of environmental adaptations in the project:

– Solid wood in all load-bearing structures, ceilings, auditorium, parts of the roof

– Wood in all interior and exterior walls

– High degree of precut materials

– Low carbon concrete class A

– Flooring with a low greenhouse gas footprint

– Waste: 99% sorting rate, 79% material recycling

– Energy: Solar cells on the roof and local, waterborne heating (also used during the construction period)

Involve the recycler from the start

Anita Storli represents Norsk Gjenvinning, which was responsible for commercial waste from the project. She said that the project has achieved a very high degree of both sorting and material recycling, thanks to early involvement.

– “It’s absolutely essential to get good results that we are involved right from the start-up meeting and follow the process. In this project, Backe Oppland has involved us right from the start, which is why we managed to achieve a 99% sorting rate and 79% material recycling rate,” she explained. Storli also highlighted other success criteria, such as ensuring resource-efficient packaging for the products, working with precap and returning as much as possible of what can be returned, such as pallets. “Waste should always be part of the construction meetings, so that you can follow the statistics and intervene when things don’t go as planned,” Storli said.

Upcoming breakfast seminars from project Climate-friendly buildings Innlandet:

About Climate-friendly buildings Innlandet

Project (2023-2026) that will contribute to more climate-friendly construction in inland Norway

Funded by Innlandet County Council and Innovation Norway

Focus areas: Climate-friendly materials and building systems

Target group: The entire value chain, from client to developer, architect, contractor and building product supplier.

The project will raise competence in areas such as

– Greenhouse gas calculations

– Climate footprint for different materials and systems

– Certification schemes for climate-friendly buildings

– Reuse and repurpose

– Financing schemes

Duration: 2023-2024-2025

The project is run by Norwegian Wood Cluster, Civitas and Norconsult

More info at www.klimavennligebygg.no